The rapid growth of wireless communication motivated us to

use computers and mobile phones to remotely control a household appliance.

In the Residential

Environment, We found that

there are a lot of loads (i.e. Electronic Devices) with different mechanical

switch. To power any device one need to use the corresponding switch for it, so

for someone in the bedroom that want to switch on the Refrigerator when there

is light and switch off the Refrigerator when light has gone off, such an

individual will need to work down to the location of the power switch for each

situation, This is time consuming and Energy lost. Consider this same person

wants to power on all the security light in the house when night arrives and

power off all the security light during morning time, the same person wants to

power on the electric kettle, wants to on the water tap, wants to pump water to

the house and so many things he/she wants to do, a lot work is required

From this situation

cited above, we can see the problem in the house, a lot of Energy is lost, and

time wasted and so on…

How can we solve this

problem….Remote Control….

·

Our aim is to be able to have access to the appliances

in the house or any other place i.e. the Refrigerator, the security light, the

TV, the Electronic Device, the pumping machine, the house tap, the electric

kettle, from a remote location that is without using a switch to control the

appliance.

·

To be able to monitor the activities of our Electrical

Appliances via a remote location

This research paper would concentrate on the methods

of developing a system that will have

the ability to control the appliances of the house from the security light to

the TV in the sitting room to Air Conditional in the bedroom to the refrigerator

in the kitchen to all Electrical Device. This would prove to be particularly

helpful in the house environment even Industry in which device could be

controlled remotely.

We would also go further to examine the

different techniques to achieve a solution for this problem. We would also

examine the working principle of the system we developed.

·

To solve this problem will face in our household activities.

·

To implement a remote control of household appliances

using our mobile phones and the computer system

The proposed solution will need to be

easy to use, simple, secure, robust and be useful in most houses.

How it Works

Our System is design in such a way so that a

PC, or a mobile will connect to a wireless network in the house and this PCs

and Mobile Phones will now communicate with the PC of the Controller. So when

this PC receives this signal it sends it to the hardware that switch on the

Electrical Appliances.

The system has three main parts, namely;

·

Hardware,

·

The

Interface phase and

·

Software.

The Hardware Stage:

The Hardware architecture consists of series

of dependent circuitry that are interconnected to form the hardware part. The

Hardware is divided into two main modules. The first module known as the main module consists of the Power pack,

The Transistor Switching System and The Relay Switching System.

The Second

Module known as the load Module was design so that all the loads to be

control could be attached to it, just like multiple sockets connected so that

different loads could be plugged to them.

The Interface Stage

The Interface stage is the

process on connecting the Hardware to the Software i.e. The Computer System.

Two Techniques were considered during the development of the system

The Two Techniques are:

·

Using The NI myDAQ and

·

Using a USB to Parallel Port Cable

The NI myDAQ:

NI myDAQ is a

low-cost data acquisition (DAQ) device that gives students the ability to

measure and analyze live signals anywhere, anytime. NI myDAQ is compact and

portable so students can extend hands-on learning outside of the lab

environment using industry-standard tools and methods. The NI myDAQ is a product of National Instrument. It has 8

digital I/O port, 2 Analog I/O port , a power supply, Audio input and output and

a multimeter.

The USB to

PARALLEL PORT CABLE:

The USB to PARALLEL Port is an extension of the parallel port

for computers that don’t have the built in parallel port. It is mostly used by

old printers. Centronic or Parallel port is a simple and inexpensive tool for

building computer controlled devices and projects. The simplicity and ease of

programming makes parallel port popular in electronics hobbyist world. The parallel

port is often used in Computer controlled robots, Atmel/PIC programmers, home

automation, etc. PC parallel port can be a very useful I/O channel for

connecting your own circuits to PC. It can be used to perform some very amusing

hardware interfacing experiments.

In our Design process

the two devices were implemented in the end product so the user has the option

of using any of them for the interfacing.

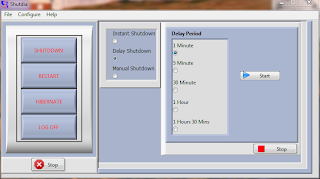

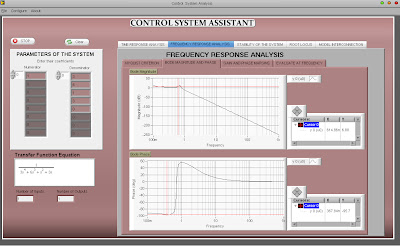

THE

SOFTWARE STAGE:

The software is stage where all the control

activities take place. The Software we used was designed and implemented using

LabVIEW Programming Language.

LabVIEW is a

graphical programming language that has been widely adopted throughout

industry, academia, and research labs as the standard for data acquisition and

instrument control software. LabVIEW is a powerful and flexible instrumentation

and analysis software system. LabVIEW departs from the sequential nature of

traditional programming languages and features an easy-to-use graphical

programming environment, including all of the tools necessary for data

acquisition (DAQ), data analysis, and presentation of results. With its

graphical programming language, sometimes called "G," you program

using a graphical block diagram that compiles into machine code. Ideal for a

countless number of science and engineering applications, LabVIEW helps you

solve many types of problems in only a fraction of the time and hassle it would

take to write "conventional" code. LabVIEW has found its way into

such a broad spectrum of virtual instrumentation applications that it is hard

to know where to begin. As its name implies, it began in the laboratory and

still remains very popular in many kinds of laboratories from major research

and development laboratories around the world (such as Lawrence Livermore,

Argonne, Batelle, Sandia, Jet Propulsion Laboratory, White Sands, and Oak Ridge

in the United States, and CERN in Europe), to R&D laboratories in many

industries, and to teaching laboratories in universities all over the world,

especially in the disciplines of electrical and mechanical engineering and

physics.

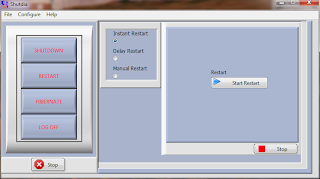

Our Software program Is divided into Two main modules the first module contains the main

programs, that one that controls the appliances. The Second module

contains the wireless communication management. It handles the communication of

other computers and mobile phones to our main system so it is basically design

for handling the wireless communication.

Our Software program Is divided into Two main modules the first module contains the main

programs, that one that controls the appliances. The Second module

contains the wireless communication management. It handles the communication of

other computers and mobile phones to our main system so it is basically design

for handling the wireless communication.

CONCLUSION

AND RECOMMENDATION

In The paper low

cost, secure, ubiquitously accessible, auto configurable, remotely controlled

solution for automation of homes has been introduced. The approach discussed in

the paper has achieved the target to control home appliances remotely using a Computer

and a Mobile phone based system satisfying user needs and requirements. The

extensive capabilities of this system are what make it so interesting. From the

convenience of a simple cell phone and the availability of a pc equipped with

wireless card, a user is able to control and monitor virtually any electrical

device in a household. By connecting all the appliances with the system through

power line communication or wireless to the system, all electrical household

appliances can be controlled by sending a signal from the wireless mobile

handset or a computer to the control device which processes the signal to

determine which appliance is to power on.

Our Recommendation is

to use our system especially the flexibility which makes it easy to redesign to

the user’s desire.

Hookes Electric Limited ® 2013